Hydraulic Body Movement: The Hidden Dance of Lowriders

The rhythmic bounce of a classic Impala chassis moving to the beat of street culture represents more than just automotive modification—it symbolizes a rich cultural movement spanning decades. Hydraulic suspension systems transform ordinary vehicles into gravity-defying expressions of art and engineering ingenuity. These systems, originally adapted from aircraft technology, have evolved from practical solutions to dramatic performance elements central to lowrider culture. The intricate network of pumps, cylinders, and switches enables precise control over vehicle stance and movement, creating a uniquely interactive driving experience. This marriage of technical innovation and cultural expression continues to influence automotive customization worldwide, demonstrating how engineering can transcend functionality to become performance art.

The Engineering Marvel Behind the Bounce

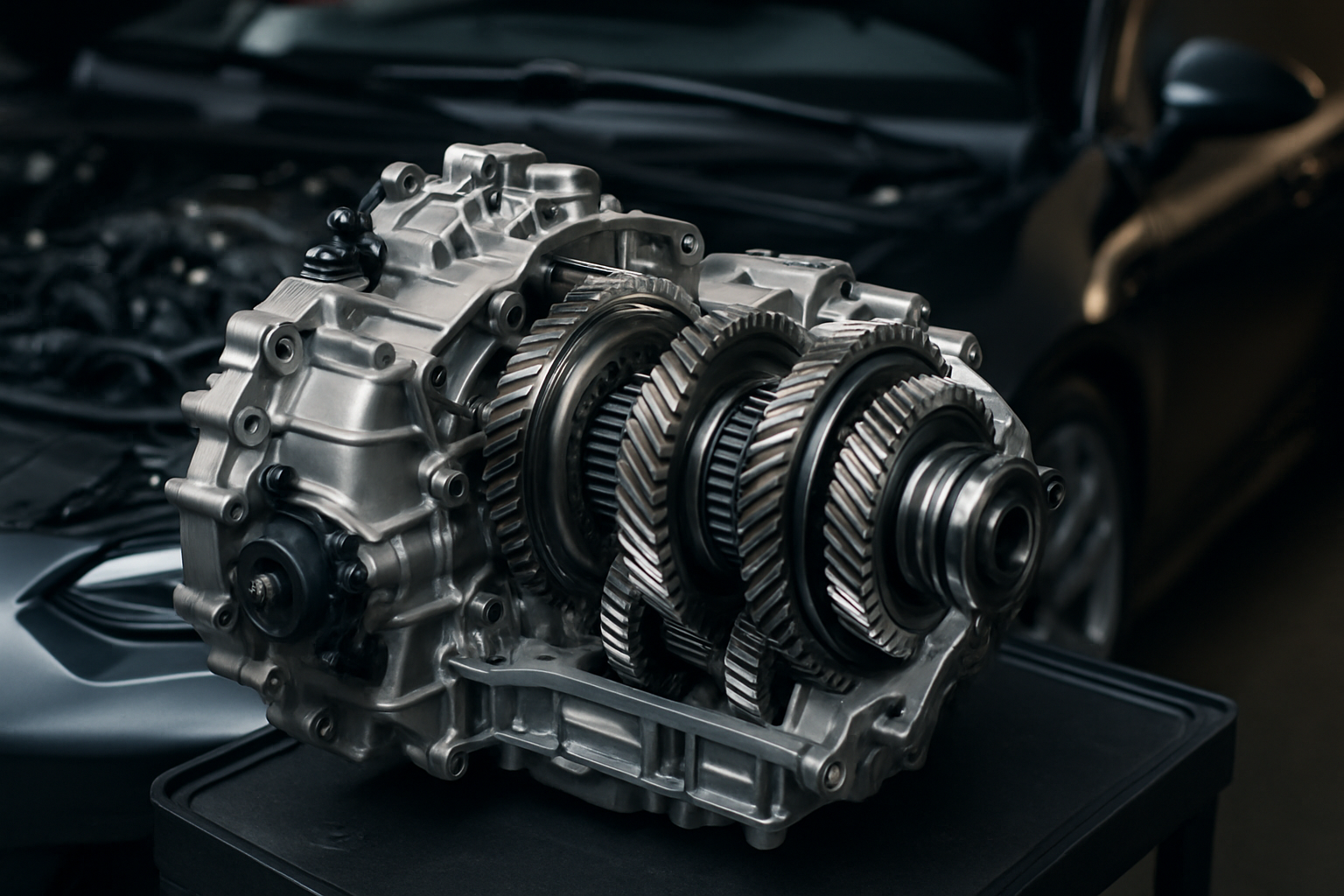

Hydraulic suspension systems operate on principles similar to those used in industrial equipment but tailored specifically for automotive applications. At their core, these systems utilize hydraulic fluid under pressure to create controlled movement. The basic components include electric pumps that pressurize the fluid, cylinders that replace conventional shock absorbers, hardlines that transport the fluid, dump valves that release pressure, batteries to power the system, and an intricate control system that allows for precise manipulation.

What makes these systems remarkable from an engineering perspective is their capacity for extreme articulation while maintaining structural integrity. The front and rear suspension points must be reinforced to handle forces they were never designed to endure in stock configuration. This often involves custom fabrication of reinforcement plates and strengthened mounting points. The hydraulic cylinders themselves must be precision engineered to provide both the dramatic lifting heights desired and the durability to withstand countless cycles of operation.

Modern systems have evolved to incorporate multiple pumps—sometimes up to four or more—allowing independent control of each corner of the vehicle. This enables not just simple up-and-down movement but complex patterns including three-wheel motion, side-to-side rocking, and the coveted “dancing” capability that has become a competitive sport in its own right.

Cultural Roots and Evolution

The origins of hydraulic suspensions in custom automobiles trace back to 1950s California, where Mexican-American communities began customizing older vehicles as expressions of identity. The initial motivation was surprisingly practical—circumventing laws that prohibited cars from being lower than their headlight height. Early innovators realized that aircraft hydraulic components could be repurposed to create adjustable ride heights, allowing drivers to lower their vehicles while parked but raise them to legal heights when driving.

By the 1970s, what began as a practical solution had evolved into an art form with cultural significance. Car clubs formed around the lowrider movement, establishing competitions and exhibitions that showcased increasingly sophisticated hydraulic installations. These gatherings became important social spaces where technical knowledge was shared and cultural traditions celebrated through automotive expression.

The 1980s and 1990s saw hydraulic systems gain mainstream recognition through music videos, films, and magazines. Artists like Ice Cube, Snoop Dogg, and Kid Frost incorporated lowrider imagery into their work, cementing the connection between hydraulic systems and hip-hop culture. This period also witnessed significant technical advancement, with enthusiasts developing faster pumps, more responsive controls, and increasingly complex movement patterns.

Today, hydraulic suspension culture represents a multimillion-dollar industry with international reach, having spread from its Chicano roots to communities across the globe. What began as a subculture has influenced mainstream automotive design, with air suspension systems in luxury vehicles owing much to the pioneering work of lowrider builders.

Technical Challenges and Solutions

Creating a reliable hydraulic suspension system presents numerous engineering challenges. Foremost among these is managing the tremendous stress placed on the vehicle frame. A standard passenger car chassis was never designed to handle the forces generated when lifting one or more corners repeatedly. This necessitates extensive reinforcement, often including full-frame wrapping with additional steel plating and custom gusseting at key stress points.

Battery management represents another significant challenge. Competition-level systems may require up to 12 batteries to power multiple high-performance pumps, adding considerable weight and requiring sophisticated electrical management. These batteries must deliver massive amperage for quick response while maintaining reliability through countless charge cycles. Advanced systems incorporate dedicated alternators, isolators, and charging systems to manage this electrical demand.

Hydraulic fluid dynamics present their own complications. Engineers and builders must carefully calculate line sizes, pump output, and cylinder dimensions to achieve the desired speed and height while minimizing heat buildup that can deteriorate seals and components. Modern systems often incorporate cooling mechanisms, pressure accumulators, and specialized fluid formulations to address these concerns.

Perhaps most impressive is the development of control systems. What began with simple toggle switches has evolved to include computerized controllers, wireless remote operation, and even choreographed movement sequences synchronized to music. Advanced builders now incorporate accelerometers and pressure sensors to enable precise control over vehicle movement and prevent damage from overextension.

Competition and Performance Standards

The competitive aspect of hydraulic suspensions has driven much of the technical innovation in the field. Events known as “hop contests” measure the maximum height a vehicle can achieve, with current records exceeding an astonishing 120 inches of lift. These competitions have distinct categories including Single Pump, Double Pump, and Radical classes, each with specific technical regulations.

Beyond simple height competitions, “dance” competitions evaluate vehicles on their ability to perform complex movement routines, often synchronized to music. Judges score based on technical difficulty, execution, creativity, and audience response. These performances require sophisticated coordination of multiple pumps and precise timing from the operator, who typically uses an array of switches to control each corner of the vehicle independently.

The standards for quality installation have risen dramatically over decades of competition. Professional builders now employ computer-aided design, custom-machined components, and aerospace-grade materials. Presentation has become as important as performance, with hydraulic installations often chrome-plated or powder-coated and displayed prominently through clear floors or specialized compartments.

Safety considerations have also evolved alongside performance capabilities. Modern competition vehicles incorporate roll cages, reinforced battery boxes, hydraulic line protection, and emergency shutoff systems. Organizations like the Lowrider Association have established comprehensive safety standards to minimize risks while allowing for spectacular performances.

Future Innovations and Preservation Efforts

The future of hydraulic suspension systems sits at an interesting crossroads of tradition and innovation. While preserving the core techniques that define the culture, builders are increasingly incorporating digital technology into their designs. Some cutting-edge systems now utilize electronic solenoid valves, pressure transducers, and microprocessor controls to achieve movements that would be impossible with traditional setups.

Environmental considerations are also driving innovation, with some builders experimenting with biodegradable hydraulic fluids and more efficient electrical systems. Weight reduction through the use of advanced materials like aircraft-grade aluminum and carbon fiber reinforcements allows for better performance with less energy consumption.

Perhaps most importantly, there is a growing movement to document and preserve the technical knowledge and cultural significance of hydraulic suspension systems. Museums like the Petersen Automotive Museum in Los Angeles have featured lowrider exhibitions, recognizing their importance in automotive history. Organizations such as the National Association of Lowrider Clubs work to document building techniques and promote education about the engineering principles involved.

Educational programs in some technical colleges now include hydraulic system design, acknowledging both the technical sophistication and cultural significance of these modifications. This academic recognition helps ensure that the knowledge developed over decades of grassroots innovation isn’t lost to time.

The hydraulic suspension system represents far more than a mere automotive modification—it stands as a testament to how engineering creativity can emerge from cultural expression, creating a unique art form that continues to evolve while honoring its roots. As automotive technology progresses toward electrification and autonomy, the hand-built, operator-controlled nature of hydraulic systems offers a compelling counterpoint to automation, celebrating the intimate connection between human, machine, and community.