Dynamic Inventory Management for Just-in-Time Manufacturing

Intelligent inventory systems reshape contemporary production landscapes by balancing demand forecasting precision with operational flexibility. These sophisticated systems eliminate excessive stockholding while ensuring production continuity, addressing a critical challenge for manufacturers competing in rapid-response markets. Beyond mere stock control, modern inventory management integrates with enterprise systems to create responsive manufacturing ecosystems that adapt to market fluctuations in real-time. Companies mastering this balance gain significant competitive advantages through reduced capital commitments and enhanced customer satisfaction.

Understanding the Evolution of Inventory Management

The journey of inventory management techniques reveals a fascinating progression from early manual stock counting to today’s sophisticated algorithms. Early manufacturing relied on visual inspections and paper ledgers, requiring substantial safety stocks to prevent stockouts. The mid-20th century brought statistical modeling that introduced economic order quantity (EOQ) calculations, allowing more scientific approaches to balancing holding costs against ordering expenses. Toyota’s revolutionary just-in-time philosophy in the 1970s fundamentally challenged conventional wisdom by demonstrating that minimal inventory could actually improve quality and efficiency. This approach demanded unprecedented supplier coordination and production reliability, setting new standards for manufacturing operations worldwide.

The digital revolution of the 1990s introduced enterprise resource planning (ERP) systems that integrated inventory data with other business functions, creating the foundation for today’s interconnected inventory ecosystems. Modern systems now incorporate machine learning algorithms that analyze historical patterns, seasonal variations, and market signals to predict demand with remarkable accuracy. This technological progression reflects a fundamental shift in thinking—from viewing inventory as a necessary asset to recognizing it as a significant opportunity cost that requires sophisticated management techniques to optimize.

The Economic Impact of Precision Inventory Control

Effective inventory management dramatically influences financial performance across multiple dimensions. The most obvious benefit comes from reduced capital commitment—every dollar not tied up in excess inventory becomes available for strategic investments in equipment upgrades, research and development, or market expansion. For manufacturers with thousands of SKUs, this can translate into millions in freed capital. Beyond these direct savings, carrying costs typically range between 18% and 30% of inventory value annually, encompassing warehouse space, insurance, taxes, obsolescence, and opportunity costs.

Precision inventory systems also significantly reduce waste from expired or obsolete items—particularly critical in industries with perishable inputs or rapid innovation cycles. Companies implementing advanced inventory management report shrinkage reductions averaging 15-25%, representing substantial bottom-line improvements. The economic benefits extend to operational efficiency as well, with streamlined inventories requiring less handling, reduced warehouse space, and decreased labor costs. Perhaps most significantly, optimized inventory positions businesses to respond quickly to market opportunities, turning inventory management from a cost center into a strategic advantage that directly enhances revenue potential.

Technological Foundations of Modern Inventory Systems

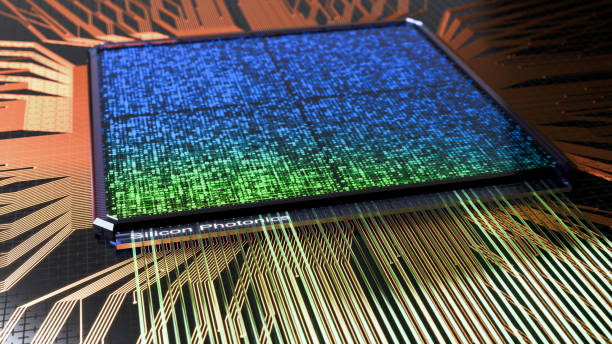

Today’s inventory management infrastructure relies on sophisticated technology stacks that enable unprecedented visibility and control. At the foundation are robust database systems that maintain real-time inventory positions across multiple locations, often integrated with supplier and customer systems for complete supply chain transparency. RFID and IoT sensors provide automated tracking capabilities that eliminate manual counting errors while providing continuous visibility into inventory movement and conditions. Advanced analytics platforms layer on top of these data sources, applying statistical models and machine learning algorithms to identify patterns and predict future requirements with increasing accuracy.

Digital twins—virtual replicas of physical inventory systems—allow managers to simulate different scenarios and optimize parameter settings before implementation. Cloud-based inventory platforms enable real-time collaboration across global operations, ensuring consistency while accommodating local variations in demand patterns and supply constraints. Mobile technologies extend these capabilities to the warehouse floor, empowering workers with immediate access to inventory data and decision support tools. Together, these technological components create a responsive ecosystem that automatically adjusts to changing conditions while providing managers with actionable intelligence for strategic decisions.

Implementation Strategies for Manufacturing Environments

Successful inventory optimization requires a carefully structured implementation approach that balances immediate efficiency gains with long-term capability building. The journey typically begins with comprehensive inventory segmentation using ABC/XYZ analysis to identify which items deserve the most sophisticated management techniques. This prioritization ensures resources are allocated where they’ll generate the greatest return. Cross-functional teams including operations, finance, sales, and IT must collaborate to establish appropriate inventory policies that balance service level objectives against holding costs for each segment.

Data quality represents a critical success factor—many implementation efforts fail due to inaccurate master data, highlighting the importance of rigorous data cleansing before system deployment. Pilot implementations focused on high-value inventory segments allow organizations to refine processes before full-scale deployment. Training becomes essential as responsibilities shift from manual record-keeping to data analysis and exception management. The most successful implementations incorporate regular review cycles that continuously reassess inventory parameters against changing market conditions. Organizations must also develop clear performance metrics that go beyond simple inventory turns to incorporate service levels, working capital efficiency, and forecast accuracy to drive continuous improvement.

Future Directions in Manufacturing Inventory Control

Emerging technologies promise to further revolutionize inventory management practices in the coming decade. Artificial intelligence systems will move beyond simple demand forecasting to incorporate complex external variables including social media sentiment, weather patterns, and competitive actions into predictive models. These systems will increasingly operate autonomously, making inventory adjustments without human intervention while explaining their decisions through natural language interfaces. Integration with advanced manufacturing technologies like 3D printing may fundamentally reshape inventory requirements, enabling on-demand production that eliminates finished goods inventories entirely for certain product categories.

Blockchain and distributed ledger technologies will likely transform multi-enterprise inventory visibility, creating tamper-proof records of inventory movements across partner organizations while enabling new contracting models based on verified consumption. Quantum computing applications, still in their infancy, may eventually solve complex multi-echelon inventory optimization problems that remain computationally prohibitive with current technologies. The environmental impact of inventory practices will receive increased attention as sustainability concerns drive interest in circular supply chains that minimize waste through precise inventory control. Organizations that anticipate these developments and build adaptable inventory management capabilities will secure lasting competitive advantages in increasingly dynamic markets.

Strategic Implementation Guidelines

-

Begin with a comprehensive inventory classification using multiple factors beyond just value—include supply risk, demand variability, and lead time volatility

-

Establish tiered service level objectives aligned with customer priorities rather than applying uniform policies across all inventory items

-

Implement statistical safety stock calculations that factor in both demand and supply uncertainties

-

Create clear inventory ownership with designated responsibilities for different aspects of inventory management

-

Develop supplier scorecards that specifically measure inventory performance metrics

-

Establish regular S&OP (Sales and Operations Planning) processes that align inventory strategies with broader business objectives

-

Incorporate inventory metrics into executive dashboards to maintain leadership focus

Modern inventory management has evolved far beyond simple stockkeeping into a strategic discipline that directly influences competitive positioning. Organizations mastering this discipline create significant advantages through capital efficiency, operational agility, and enhanced customer responsiveness. As technologies continue advancing, the gap between leaders and laggards will likely widen—companies that invest in developing sophisticated inventory capabilities today position themselves for sustained success in increasingly dynamic manufacturing environments. The future belongs to organizations that recognize inventory not as a necessary cost of business but as a strategic lever for competitive advantage.